Experimental study on a gold ore in Laos with environment-friendly GDA leaching reagents

Guo Pengzhi, Qiu Sha, Wu Yipeng, Kang Weipang

Tianjin North China Geological Exploration Bureau, Tianjin 300170, China

Abstract: a leaching experiment with environment-friendly GDA reagents was selected by the B. Phatem carbonate type gold ore in Bak-ou county, Luang Pracang province of Laos. The results indicate that under the condition of grinding fineness of 0.074mm account more than 90%, pulp concentration 40%, lime dosage 3kg/t, pretreatment time with alkali 2h, dosage of “GDA” reagents 600 g/t, leaching time 24h, the gold leaching rate up to 96.40%. Compared with the cyanide leaching process, the gold leaching rate with the “GDA” leaching increase 1.4%, while the dosage amount reduce 200 g/t, leaching time shorten more than 12h. leaching toxicity analysis of the tailings was studied. The results suggest that the amount of cyanide, Pb, Zn, As in the tailings was under the national standard limit. Therefore, the leaching tailings can directly discharge without detoxification treatment. The economic comparative analysis shows that the “GDA” leaching process can reduce production cost of 3,930,000 RMB/year.

Key words: gold beneficiation reagent; “GDA”, cyanide leaching; leaching toxicity

Received date: 2015-02-07

Introduction of Author: Guo Pengzhi (1971 -), male, Shangqiu, Henan Province, Master, senior engineer of dressing, the assistant commissioner of the Tianjin North China Geological Exploration Bureau, mainly engaged in mine management, resource development and utilization research, business management and other work.

At the 2007 China International Mining Conference, the Ministry of land and resources proposed the green mining target in order to the coordinated development of the mineral resources development and environmental protection (Liu, 2011). According to this new requirement and development situation, more and more attention is paid to the research and application of non cyanide leaching gold technology. At present, there are many methods of non cyanide leaching gold, including thiourea method (Guo et al., 1994; Li et al., 2014), thio sulfate method (Elmer et al., 2001), halogenation method (Li et al., 2004), microbial method, and the LSSS method and so on (Yang et al., 2007;Wang et al., 2010; Li et al., 1992).

But these processes are usually used large quantities of medicament with high cost, and can not be applied in industry (Kenneth, 1992). In recent years, new environment-friendly gold leaching agent have been reported (Huang, 2011; Que, 2011, Teng et al., 2012; Xiong, 2013; Liu et al., 2013), and there were new environmentally friendly gold leaching reagents in the domestic market, such as "northeast tiger", "cicada", "Jin Xin", then the research of the environmental gold leaching agent has entered into a rapid development stage. B. Phatem gold deposite in Bak-ou county, Luang Pracang province of laos is located in the area with more developed water system and more underground karst cave. In order to reduce the pollution to the surrounding environment, reduce risk and ensure mine development project for the implementation of security, it is necessary to carry out environmental protection leaching of gold.

In this paper, a leaching experiment with environment-friendly GDA agents was adopted to B. Phatem gold deposite in Bak-ou county, Luang Pracang province of Laos.

1. Ore properties

1.1 Multi element analysis of ore

The results of multi element analysis of ore are shown in Table 1. The results suggest that the only valuable element in the ore is gold with content of 7.5 G / T, and there is minor silver, and the contents of copper, lead, zinc, arsenic and other elements in the ore is very low. The carbon content of the ore is 10.94%, but the further analysis indicates that the carbon is mainly inorganic carbon, which will not affect the cyanide leaching.

1.2 Mineral component of ore

The main mineral composition of the ore is shown in Table 2. The above ore properties shows that the gold deposit is a gold bearing carbonate type, and the mineral composition is relatively simple. The content of arsenic and other harmful impurities is low, and the content of coarse grained gold in the ore is low. The gold in the ore is embedded with medium and fine grained, and the content of the package gold is very low. The gold particles are mostly monomer dissociation and exposed state.

Table 1 The results of multi element analysis of ore (%)

elements |

Au* |

Ag* |

Cu |

Pb |

Zn |

contents |

7.5 |

2.86 |

0.005 |

0.007 |

0.001 |

elements |

S |

TFe |

As |

C |

CaO |

contents |

0.17 |

0.15 |

0.007 |

10.94 |

52.06 |

elements |

MgO |

SiO2 |

AL2O3 |

||

contents |

0.34 |

5.47 |

0.24 |

Note: the unit of *Au, Ag is g/t.

Table 2 The main mineral composition of the ore

Minerals |

Relative content (%) |

||||

Metallic minerals |

Pyrite |

0.05 |

|||

Arsenopyrite |

0.01 |

||||

Copper minerals |

0.10 |

0.52 |

|||

limonite |

0.2 |

||||

Other oxidized iron ore |

0.16 |

||||

quartz |

4.56 |

||||

Non metallic minerals |

Calcite, dolomite |

and |

other |

89.12 |

99.48 |

carbonate minerals |

|||||

Sericite, chlorite |

5.80 |

||||

Total |

100 |

||||

1.3 Occurrence state of Gold

The ore was analyzed by chemical phase method, and the occurrence state of gold minerals in the ore was examined. The results of the analysis are shown in Table 3. The results indicate that there is a single form of gold in the ore, and the content of the package gold is very little with the content of 3.74%. Among them, the relative content of the package gold in quartz and silicate mineral is 1.34%, and the relative content of the package gold in sulfide deposit is 2.40%. The other is bare and half-bare gold with grade 7.2 g / T, which accounted for 96.26% in the content of gold of the raw ore.

Table 3 The results of the gold phase analysis

Phase of gold |

Grade (g/t) |

Relative content (%) |

|

inclusion gold in the quartz and silicate |

0.10 |

1.34 |

inclusion gold in the pyrite |

0.00 |

0.00 |

inclusion gold in the limonite |

0.00 |

0.00 |

|

inclusion gold in the sulphide minerals |

0.18 |

2.40 |

|

inclusion gold in the carbonate minerals |

0.00 |

0.00 |

|

Exposed and semi-exposed gold |

7.20 |

96.26 |

total |

7.48 |

100.00 |

1.4 Grain size characteristics of gold

Based on the microscopic observation and artificial placer analysis, the gold minerals in the ores are mainly medium and fine-grained and disseminated, and the coarse gold particles and micro gold have less content. Among them, the content of gold with grain size of 0.037-0.074 mm is up to 61.2%, and the content of gold with grain size of 0.074-0.01 mm is up to 24.84%. However, the content of gold with grain size less than 0.01mm is lower and only 5.64%. The statistical results are shown in Table 4.

Table 4 The results of particle size measurement

|

grain size (mm) |

coarse |

middle |

fine |

Fine particle and sub micro |

total |

0.295-0.074 |

0.074-0.037 |

0.037-0.01 |

<0.01 |

||

|

Relative content (%) |

8.32 |

61.20 |

24.84 |

5.64 |

100.00 |

The above study of the ore properties shows that the gold deposit is a gold bearing carbonate type, and the mineral composition is relatively simple. The harmful impurities, such as arsenic, are relatively low. The content of large particle gold is also relatively low, and is mainly medium and fine grained and disseminated. The content of inclusion gold is very low, and the inclusion gold is mostly single and exposed.

2. Experimental study

2.1 Exploratory experiment

In terms of the nature of this gold mine, the design of the construction project of the B. Phatem gold deposit, Laos is complete mud cyaniding solution. The four stage leaching and five stage leaching process were adopted. The experiment conditions are as following: the content of gold with grain size of 0.074 mm is more than 90%, the slurry concentration is 40%, and the lime dosage is 3 kg / T, the sodium cyanide dosage is 800g / t, and the leaching time is 38 h. Then, the leaching rate is up to 95% under the above conditions.

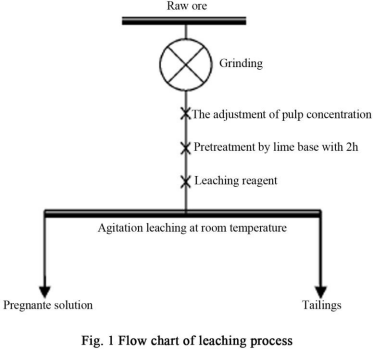

In order to contrast and validate the “GDA” leaching effect, we firstly carried out two sets of the contrast leaching test between the “GDA” reagent and the sodium cyanide, based on the parameters for process design of mines. The leaching equipment is a leaching mixer of XJT / RK type carrying out at room temperature. The leaching tailings are dried, then concentrated to sampling. We analysis the grade and calculate the leaching rate. The leaching process is shown in Figure 1.

Table 5 The comparison test results of leaching

Ore feed grade / (g/T) |

reagent |

Tailings grade/(g/t) |

Leaching rate/% |

7.5 |

Sodium cyanide |

0.28 |

96.27 |

“GDA” |

0.26 |

96.53 |

|

11.2 |

Sodium cyanide |

0.42 |

96.22 |

“GDA” |

0.30 |

97.30 |

Test conditions are as following: the content of the grinding fineness of 0.074mm is 90%, and the slurry concentration is 40%. The amount of lime is 3 kg / T with the time of pretreatment of 2h. The amount of leaching agent is 800 g / T with the time of leaching 32 h. During the experiment, the leaching agent is added at once after the alkali treatment is completed. Comparison test results of leaching are shown in Table 5.

The comparison test results of leaching indicate that the leaching effect of the “GDA” reagent is very well for the type of gold ore. Given the ore grade is 7.5 g/t, the grade of leaching tailings is 0.26 g/t with leaching rate up to 96.53%, which is better than sodium cyanide leaching. When the ore grade is 11.12 g/t and the amount of leaching agent is still 800 g/t, the grade of leaching tailings is 0.30 g/t with leaching rate up to 97.53% using the “GDA” reagent. However, the grade of leaching tailings increased to 0.42 g/t and the leaching rate is 96.22% using the sodium cyanide leaching. The difference of these two methods is up to 1.08%. Compared with the sodium cyanide leaching, obviously, the “GDA” cyanide leaching has better leaching effect with lower reagent consumption. In order to optimize the process parameters, it is necessary to carry out the condition test for the “GDA” leaching of the gold ore in the B. Phatem gold deposit, Laos.

2.2 Condition test

The procedure of the conditional test is shown in Figure 1. The condition tests include grinding fineness, lime dosage, "GDA" dosage, pulp concentration, and leaching time. The ore grade is 7.5 G / T, and the pretreatment time is 2h using the stirring leaching at room temperature.

2.2.1 Grinding fineness test

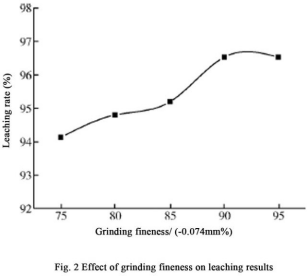

Experimental conditions are as follows: the slurry concentration is 40%, and the lime dosage is 3 kg / T. The “GDA” dosage is 800g / T, and the leaching time is 32 h. The effect of grinding fineness to the leaching results is shown in Figure 2.

The results from the Figure 2 show that the leaching rate of gold is 94.13% when the content of the grinding fineness of 0.074 mm is 75%. The leaching rates of gold increase with the improvement of grinding fineness. The leaching rate of gold is up to 96.53% when the content of the grinding fineness of 0.074 mm is 90%. Then, The leaching rate of gold is constant with the improvement of grinding fineness. Therefore, the selected content of the grinding fineness of 0.074 mm is 90%.

2.2.2 Lime dosage test

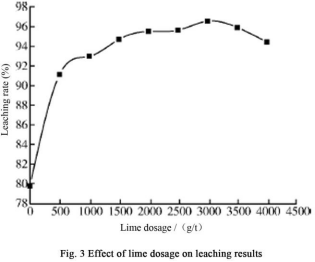

Experimental conditions are as follows: The content of the grinding fineness of 0.074 mm is 75%, and the slurry concentration is 40%. The “GDA” dosage is 800g / T, and the leaching time is 32 h. The effect of Lime dosage to the leaching results is shown in Figure 3.

The results of the Figure 3 show that the leaching effect is bad without lime, and the leaching rate of gold is only about 80%. With the lime dosage increase, the leaching rate of gold increase. When the lime dosage is 3 kg/t, the leaching rate of gold is up to 96.53%. When the lime dosage is more than 3 kg/t, however, the leaching rate of gold is decrease, which indicates that the more lime dosage make against the gold leaching. Therefore, the lime dosage is 3 kg/t.

2.2.3 "GDA" dosage test

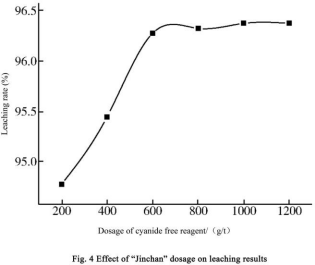

Experimental conditions are as follows: The content of the grinding fineness of 0.074 mm is 90%, and the slurry concentration is 40%. The lime dosage is 3 kg/ T, and the leaching time is 32h. The effect of "GDA" dosage to the leaching results is shown in Figure 4.

The results show that the leaching rates increase gradually with the “GDA” dosage from 200 g/t to 600 g/t. The leaching rate of gold is 94.80% with the “GDA” dosage of 200 g/t, while the leaching rate of gold is 96.27% with the “GDA” dosage more than 600 g/t. Then, the leaching rate of gold is no longer significantly improved. Therefore, the “GDA” dosage is 600 g/ t.

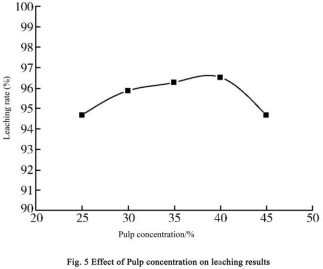

2.2.4 Pulp concentration test

Experimental conditions are as follows: The content of the grinding fineness of 0.074 mm is 90%, and the lime dosage is 3 kg/ T. The “GDA” dosage is 600 g/ T and the leaching time is 32h. The results of the test are shown in Figure 5.

The results show that the leaching rates increase gradually with the pulp concentration from 25% to 40%. The leaching rate of gold is maximum value and 96.40 % with the pulp concentration of 40%. Then, the leaching rate of gold decreases when the pulp concentration is more than 40%, which indicate that the high pulp concentration make against the gold leaching. Therefore, the pulp concentration is 40%.

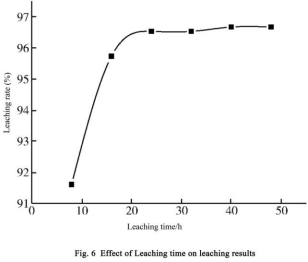

2.2.5 Leaching time test

Experimental conditions are as follows: The content of the grinding fineness of 0.074 mm is 90%, and the slurry concentration is 40%. The lime dosage is 3 kg/ T and the “GDA” dosage is 600 g/ T. The results of the test are shown in Figure 6.

Table 6 Validation test results

Sample weight /kg |

Ore feed grade/(g/t) |

Trailing grade/(g/t) |

Leaching rate (%) |

0.8 |

7.5 |

0.27 |

96.4 |

1.6 |

7.5 |

0.27 |

96.4 |

2.4 |

7.5 |

0.27 |

96.4 |

As shown in Figure 6, the leaching rate of gold is constant after the increase during the leaching time from 8h to 48h. The leaching rate of gold is up to 95.73% when the leaching time is 16 h, while the leaching rate of gold is up to 96.40% when the leaching time is 24h. Then, the leaching rate of gold is constant with the extent of the leaching time. Therefore, the selected leaching time is 24 h.

2.3 Verification test

In order to verify whether the obtained process conditions can obtain a stable leaching rate, a validation test is carried out. Validation test conditions are as following: The content of the grinding fineness of 0.074 mm is 90%, pulp concentration is 40%, lime dosage is 3 kg/t, alkali pretreatment time is 2 h, the “GDA” dosage is 600 g/t and the leaching time is 24h. The results of the test are shown in Table 6.

The results indicate that the leaching rate of gold is very stable under the optimum leaching condition, and is up to 96.40% with the trailing grade of 0.27 g/t. Moveover, compared with the method of sodium cyanide leaching, the dosage of reagent can reduce 200 g/t with the “GDA” leaching, and the leaching time can reduce more than 12 h and the leaching rate can increase 1.4%.

2.4 Analysis of leaching of precious liquid and toxicity of tail slag leaching

We carried out the sampling and chemical analysis for the leaching solutions of the sodium cyanide leaching and the “GDA” leaching respectively, and carried out the toxicity analysis of the trailing of the “GDA” leaching. The toxicity analysis of the trailing of the “Jinchuan” leaching was completed by Advanced Standards Technical Services Co., LTD. The analysis of main components in the pregnante solution of the “GDA” leaching is shown in Table 7, and the toxicity analysis of the trailing of the “GDA” leaching is shown in Table 8.

Table 7 Analysis of main components in the extract of the pregnante solution (mg / L)

|

Content of elements |

cyanide |

Au |

Ag |

Cu |

Pb |

Zn |

As |

p H value |

cyanide |

210 |

2.72 |

1.06 |

2.3 |

0.03 |

0.04 |

0.05 |

11.5 |

“GDA” |

< 0.004 |

2.88 |

1.02 |

0.65 |

0.02 |

0.04 |

0.09 |

12 |

Table 8 The toxicity analysis of the trailing of the “GDA” leaching /(mg / L)

Test item |

cyanide |

Cu |

Pb |

Zn |

As |

The results |

<0.004 |

0.26 |

<0.07 |

<0.02 |

<0.0001 |

|

National standard limit |

5 |

100 |

5 |

100 |

5 |

The results of the Table 7 and 8 indicate that the content of cyanide and copper are 210 mg/L and 2.3 mg/L in the pregnante solution of the sodium cyanide leaching process respectively. In contrast, the content of cyanide and copper are less than 0.004 mg/L and 0.65 mg/L in the pregnante solution of the “GDA” leaching process respectively. Obviously, the content of cyanide and copper in the pregnante solution decrease largely.

However, by the different leaching reagents, the contents of Pb, Zn, As and the pH values in the pregnante solution are similar. The toxicity analysis of the trailing of the “Jinchuan” leaching indicates that the content of cyanide is lower than 0.004 mg/l, and the toxicity value of the leaching Cu, Pb, Zn and As are more lower than the limit value of leaching toxicity in the hazardous waste (National standard GB5085.3-2007). Therefore, the leaching tailings of the “GDA” leaching process can directly discharge without detoxification treatment.

3.Economic comparative analysis

In order to evaluate the effect of sodium cyanide and “GDA”, we carried out the comparative analysis for the investment of mine construction, the cost of tailings detoxification, the purchase cost of leaching reagent, based on the design parameters of construction project in the B. Phatem carbonate type gold ore in Bak-ou county, Luang Pracang province of Laos, which is proposed by the Tianjin North China Geological Exploration Bureau. The primary data are from the preliminary design report of mine construction, including the scale of mine production 500 t / d, the annual working days 300 d, the construction investment of the tailings slurry detoxification treatment station 4,150,000 RMB.4 million 150 thousand yuan. The reagents prices is based on the current market price.

1)Pre construction investment

If the cyanidation process is selected, then, the construction of the detoxification of the tailing slurry processing will spend 4,150,000 RMB. However, the “GDA” leaching process does not require construction of tailing pulp treatment station.

2)The cost of detoxification of tailings slurry.

In the preliminary design, the unit cost of the detoxification of trailing is 31.01 RMB/ T, then, the cost detoxification is 4,651,500 RMB/year. However, the “GDA” leaching does not need detoxification for the tailing pulp, which is in line with national standards and can directly press dry row.

3)Purchase cost of leaching reagents

According to the preliminary design, the dosage of sodium cyanide is 800 g / T, and the market price is 18,000 RMB / T, thus, the purchase cost of sodium cyanide is 2,160,000 RMB/year. In contrast, the dosage of “GDA” is 600 g / T, and the market price is 24,000 RMB / T, thus, the purchase cost of “GDA” is 2,880,000 RMB/year.

Based on a comprehensive analysis for the above three aspects of the cost, when the cyanide process is selected, the cost for the detoxification of the tailings pulp and sodium cyanide is 6,811,500 RMB/year, while this cost for the “GDA” leaching is only 2,880,000 RMB/year.

The production cost can save 3,931,500 RMB/year. Furthermore, the “GDA” leaching process does not require construction of tailing pulp treatment station, which can save construction investment of 4,150,000 RMB.

4.Conclusion

1)Experimental study shows that the optimum conditions for the “GDA” leaching are the content of the grinding fineness of 0.074 mm is 90%, pulp concentration is 40%, lime dosage is 3 kg/t, alkali pretreatment time is 2 h, the “GDA” dosage is 600 g/t and the leaching time is 24h.

The leaching rate of gold is up to 96.40% under the above conditions.

2)In terms of the B. Phatem carbonate type gold ore, compared with the sodium cyanide leaching, the leaching rate of the “GDA” increase 1.4% and the reagents dosage reduce 200 g/t. The leaching time reduces more than 12h.

3)The toxicity analysis of the trailing of the “GDA” leaching indicates that the content of cyanide is less than 0.004 mg/L, the content of copper is 0.26 mg/L, the content of Pb is less than

0.07 mg/L, the content of Zn is less than 0.02 mg/L, and the content of As is very lower. The above results are much lower than the limit value of leaching toxicity in the hazardous waste (National standard GB5085.3-2007). Therefore, the leaching tailings of the “GDA” leaching process can directly discharge without detoxification treatment.

4)The economic comparative analysis indicates that if the “GDA” leaching process is selected by the B. Phatem carbonate type gold ore in Bak-ou county, Luang Pracang province of Laos, which is carried out by the Tianjin North China Geological Exploration Bureau, the cost will save 3,931,500 RMB/year and the pre construction investment will reduce 4,150,000 RMB.

Reference

Liu, Y.Q., 2011. Current Situation and Prospect of Green Mine Construction. Conservation and Utilization of Mineral Resources 5-6, 4-8. (in Chinese with English abstract)

Guo, G.F., Hu, Y.H., Qiu, G.Z., 1994. A theoretical study on gold leaching by thiourea: dissolution kinetics of gold. Gold 15, 30-33.(in Chinese with English abstract)

Li, J.S., Lu, Z., Zhou, W.N., 2014. A method for leaching gold by thiourea.China: CN1037 89546A[P]

Elmer, M.G., Li, L., Li, C.G., 2001. A review of gold leaching with sulfur.Metallic Ore Dressing Abroad 5, 2-18.

Li, G.C., Lu, S.C., 2004. Experimental investigation for iodide leaching of gold. China Mining Industry 13, 66-68. (in Chinese with English abstract)

Yang, J.W., Wang, E.J., 2007. Progress of mineral processing and metallurgy for gold ores. Conservation and Utilization of Mineral Resources 4, 34-38. (in Chinese with English abstract)

Wang, H., Hu, X.Z., 2010. Review of gold-leaching technologies by cyanidation and non-cyanidation. Yunnan Metallurgy 39, 9-12. (in Chinese with English abstract)

Li, D.L., Qiu, G.Z., Wang, D.Z., 1992. Initial study on the purification of cyanide-bearing liquid waste by hydrogen peroxide method. Gold 13, 32-36. (in Chinese with English abstract) Kenneth, N.H., 1992. Development trend and Prospect of leaching method.Wet Metallurgy 4,

36-42.

Huang, Q.X., 2011. Non pollution mineral processing additive and preparation method and application.China:CN102121067A[P].

Que, M., 2011. Mineral processing additive for gold mine and preparation method.China:CN1

02166545A[P].

Teng, P.G., Huang, Q.X., Long, Y., et al., 2012. Production and use method of environmental protection type precious metal mineral processing agent.China:CN102321807A

[P].

Xiong, B.L., 2013. Environment friendly type gold mineral processing agent and production method.China: CN103060577A [P].

Liu, J., Song, M.W., Yu, H.P., et al., 2013. A method for extracting gold from gold mine with ferricyanide. China: CN103290232A[P].