What is GDA?

GDA(Gold Dressing Agent)is a new high-tech product which is invented by Guangxi Senhe High Technology Co Ltd.in2010. The product is used in gold extraction directly as the substitute for sodium cyanide, without changing the original process and equipment. GDA is a non-hazardous chemical, with advantages such as low toxicity, environmental protection,high recovery,good stability,convenient operation,low dosage,low cost and convenient storage and transportation.

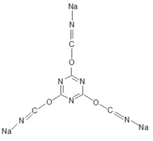

Main Composition of GDA:Carbonized sodium cyanate C6Na3O3H3N6

Molecular structure:

The reaction with gold is:C6Na3O3H3N6+Au+H2O+O2→Au(C6Na3O3H3N6)2+NaOH

Using conditions of GDA:Strong chelate with gold will be produced in the alkaline condition of PH value ±11.5.

Application scopes : gold/silver ore extraction,inhibitor for nonferrous metals,de-plating of electronic waste,electroplating and so on.

Applicable ores for GDA :

conventional oxidized gold (silver) ore, primary gold (silver) ore, gravity process tailings, flotation gold (silver) concentrate, etc.

Applicable to traditional NaCN process : CIP,heap leaching,pool leaching,on-site leaching.

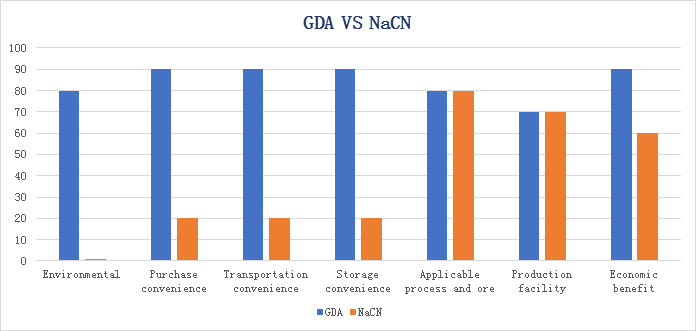

Advantages of GDA:

-Environment-friendly (GDA has been tested by the authority and certified as a common chemical)

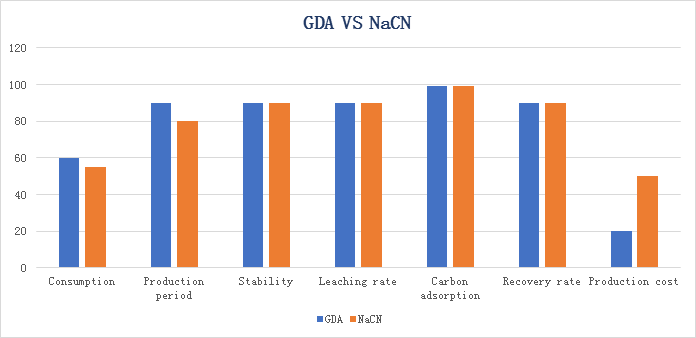

-High leaching rate (GDA can completely reach or even exceed the leaching rate of sodium cyanide)

-Good stability (Main component C6Na3O3H3N6 of GDA is not easy to be decomposed in alkaline condition)

-Faster leaching (GDA is added with an appropriate amount of leaching additives, which will accelerate the reaction between C6Na3O3H3N6 and gold)

-Less comsumption (After numerous production data surveys, the amount of GDA used in gold mines is very close to that of sodium cyanide. Compared with the previous eco-friendly gold extraction agents, the amount of GDA used is at least 4/5 less)

-Convenient usage(GDA could be used directly, without any change of traditional process conditions of sodium cyanide)